Foam Protective Packaging: Benefits, Applications, and Sustainable Solutions

In today’s fast-paced world, the need for efficient, reliable, and eco-friendly packaging solutions has never been more critical. Foam protective packaging stands out as a versatile and innovative option, providing superior protection for a wide range of products. Advanced Protective Packaging, a leader in the industry, offers custom-designed foam protective packaging solutions that cater to the specific needs of various sectors, including electronics, automotive, and healthcare. This article will explore the benefits, applications, and sustainability aspects of foam protective packaging, and how it contributes to the overall success of your product.

Benefits of Foam Protective Packaging

Superior Protection

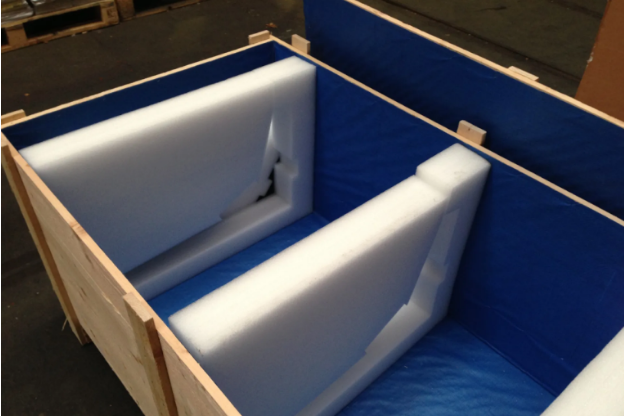

Foam protective packaging is renowned for its exceptional cushioning properties. Made from durable polyethylene foam, this type of packaging absorbs and distributes impact forces, significantly reducing the risk of damage during transportation or handling. The foam’s structure consists of numerous cells that act as tiny shock absorbers, making it ideal for fragile or delicate items. Whether it’s electronic devices, automotive parts, or medical equipment, foam protective packaging ensures that products arrive safely and intact.

Versatility and Customization

One of the standout features of foam protective packaging is its versatility. It can be custom-designed to fit the unique dimensions and requirements of any product. Advanced Protective Packaging specializes in creating tailored solutions, offering everything from bespoke designs to simple stock products. This customization ensures that every product receives the exact protection it needs, enhancing both the safety and presentation of the item.

Moisture and Chemical Resistance

Polyethylene foam protective packaging is resistant to moisture, chemicals, and temperature fluctuations, making it suitable for a wide range of applications. For instance, electronic components and medical devices often require protection from environmental factors during shipping and storage. The foam’s resistance to these elements prolongs the lifespan and functionality of the packaged products, ensuring they reach their destination in optimal condition.

Applications of Foam Protective Packaging

Electronics

In the electronics industry, the safe transport of sensitive devices is paramount. Foam protective packaging provides the necessary cushioning to prevent damage from shocks, drops, and vibrations. Whether it’s smartphones, tablets, or computer components, polyethylene foam ensures these items remain secure and undamaged.

Automotive

Automotive parts, especially those that are delicate or high-value, benefit greatly from foam protective packaging. The material’s ability to absorb impacts and its durability make it ideal for protecting car parts during transit. Additionally, custom-designed foam inserts can fit precisely around parts, reducing movement and potential damage.

Healthcare

Medical devices and equipment often require stringent packaging standards to ensure they remain sterile and functional. Foam protective packaging offers the perfect solution by providing a protective barrier against moisture and contaminants. This ensures that medical products maintain their integrity until they are ready for use.

Eco-Friendly Packaging Solutions

With growing environmental concerns, businesses are increasingly seeking sustainable packaging options. Foam protective packaging can be made from eco-friendly materials, such as recycled or biodegradable polyethylene foam. Advanced Protective Packaging is committed to providing environmentally responsible solutions, utilizing the latest printing techniques and finishes to enhance the design while minimizing environmental impact.

Sustainable Materials

Using sustainable materials in foam protective packaging not only reduces the environmental footprint but also appeals to eco-conscious consumers. By choosing recycled or biodegradable foam, businesses can demonstrate their commitment to sustainability, enhancing their brand reputation as socially responsible companies.

Read Also: Why Use a Mortgage Broker for Toronto Businesses?

Reducing Waste

Custom-designed foam protective packaging also helps in reducing waste. By creating packaging that fits the product perfectly, there is less need for excess materials. This efficient use of resources contributes to a more sustainable packaging solution, aligning with the global push towards reducing waste and promoting recycling.

Complete Packaging Solutions

Advanced Protective Packaging offers a comprehensive range of packaging solutions, from the outer carton to internal foam fitments. This holistic approach simplifies the sourcing and purchasing process for businesses, ensuring that all packaging needs are met efficiently and cost-effectively.

Streamlined Process

By providing both the outer carton and internal foam fitments, Advanced Protective Packaging reduces development time and simplifies stock control. Businesses benefit from dealing with a single supplier, which means less paperwork, balanced stock levels, and quicker responses to queries.

Additional Packaging Products

In addition to foam protective packaging, Advanced Protective Packaging supplies other essential packaging products, such as tape and bubble wrap. This ensures that businesses have access to a complete package of products, all from one trusted source. If a specific product is not in stock, it can be sourced through a network of reliable suppliers.

Expertise and Innovation

Founded in 1986, Advanced Protective Packaging has nearly 40 years of experience in the design, manufacture, and supply of protective packaging products. The company’s expertise and innovative approach make it a valuable resource for businesses seeking top-quality packaging solutions.

Custom Design Specialists

Advanced Protective Packaging’s team of custom design specialists work closely with clients to create unique, eye-catching packaging solutions. By leveraging extensive knowledge of material performance and capabilities, they ensure that each design meets the specific requirements of the project, enhancing the product’s protection and presentation.

Ongoing Evolution

The company continues to evolve, expanding its product range to include advanced materials like Nomafoam and Zotefoam. This commitment to innovation ensures that Advanced Protective Packaging remains at the forefront of the industry, offering cutting-edge solutions that meet the changing needs of businesses.

Conclusion

Foam protective packaging is a crucial element in the success of any product, providing superior protection, versatility, and eco-friendly options. Advanced Protective Packaging offers complete packaging solutions, combining expertise, innovation, and a commitment to sustainability. By choosing foam protective packaging, businesses can ensure their products are protected, their brand image is enhanced, and their environmental impact is minimized. Whether it’s for electronics, automotive, or healthcare industries, foam protective packaging is the ideal choice for safeguarding products and promoting a positive brand image.